Why Upgrade to 6 Layers?

When a 4-layer PCB no longer suffices, it’s time to consider a 6-layer board. The additional layers offer several benefits:

- More signal routing space

- An extra plane pair

- Flexibility in conductor arrangement

The key to success lies in the PCB stackup arrangement and routing strategy.

6-Layer PCB Stackup Selector 6L

Configure layer thicknesses for your 6-layer PCB stackup

Copper Layers

Prepreg Layers

Core Layers

Total Board Thickness

1.200mm

1200 µm

vs 1.2mm target:

+0 µm

| Component | Thickness |

|---|---|

| Copper (6 layers) | 210 µm |

| Prepreg (3 layers) | 456 µm |

| Core (2 layers) | 400 µm |

Stackup Visualization

SOLDER MASK (TOP)

L1 – Top SignalOUTER

35µm

Prepreg 1 (PP1)

114µm

L2 – GND PlanePLANE

35µm

Core 1 (FR-4)

200µm

L3 – Inner SignalSIGNAL

35µm

Prepreg 2 (PP2)

228µm

L4 – Inner SignalSIGNAL

35µm

Core 2 (FR-4)

200µm

L5 – PWR PlanePLANE

35µm

Prepreg 3 (PP3)

114µm

L6 – Bottom SignalOUTER

35µm

SOLDER MASK (BOTTOM)

Outer Copper

Plane (GND/PWR)

Inner Signal

Prepreg (PP)

Core (FR-4)

Solder Mask

💡 Common 6-Layer Targets

1.0mm: High-density, compact designs

1.2mm: Standard thin multilayer

1.6mm: Most common thickness

2.0mm: Power applications, thermal management

1.2mm: Standard thin multilayer

1.6mm: Most common thickness

2.0mm: Power applications, thermal management

⚡ Layer Arrangement Tips

L2 (GND) & L5 (PWR): Place planes adjacent to outer signal layers for better impedance control and EMI shielding.

L3 & L4: Inner signal layers – route high-speed signals here for protection.

L3 & L4: Inner signal layers – route high-speed signals here for protection.

Note: Final thickness may vary ±10% based on manufacturer tolerances. Always confirm stackup with your PCB fabricator before production.

Reasons to Choose a 6-Layer Board

- More surface space: Moving power and signal layers inside frees up room for components on the surface.

- Mixed-signal boards: Dedicate a surface layer to analog interfaces and use an internal layer for slower digital routing.

- High-speed, high I/O count boards: Separate signals into different layers for better organization.

Typical 6-Layer PCB Stackup

A common 6-layer stackup arrangement:

- Signal (Top)

- Ground

- Power

- Signal

- Ground

- Signal (Bottom)

Signal Routing Guidelines

- Use top and bottom layers for impedance-controlled signals.

- Thin dielectrics (≤10 mil) are preferable for these outer layers.

- For digital interfaces with differential pairs, reduced trace width allows routing to fine-pitch components.

Power Routing Strategies

- Dedicate an internal layer to power distribution.

- Break up the power plane into rails for multiple voltages if needed.

- You can still route power on signal layers using copper pour or thick traces when necessary.

High Current Considerations

For high current applications:

- Use two internal power layers interleaved with ground.

- Consider using the back layer as an additional power plane for increased current handling.

3-Core vs. 2-Core Stackup

A 3-core (or 1 thick central core with thin outer layers) arrangement is often superior:

- Increases PDN plane capacitance

- Reduces spreading inductance

- Minimizes radiated emissions from PCB edge

- Provides more consistent impedance for signals on L4

Best Practices

- Get your stackup approved by a fabrication house before layout and routing.

- Apply EMC strategies used in 4-layer and 8-layer boards.

- Consider DFM (Design for Manufacturing) guidelines throughout the process.

Remember, the stackup arrangement significantly impacts EMC and signal integrity, so choose wisely based on your specific application needs.

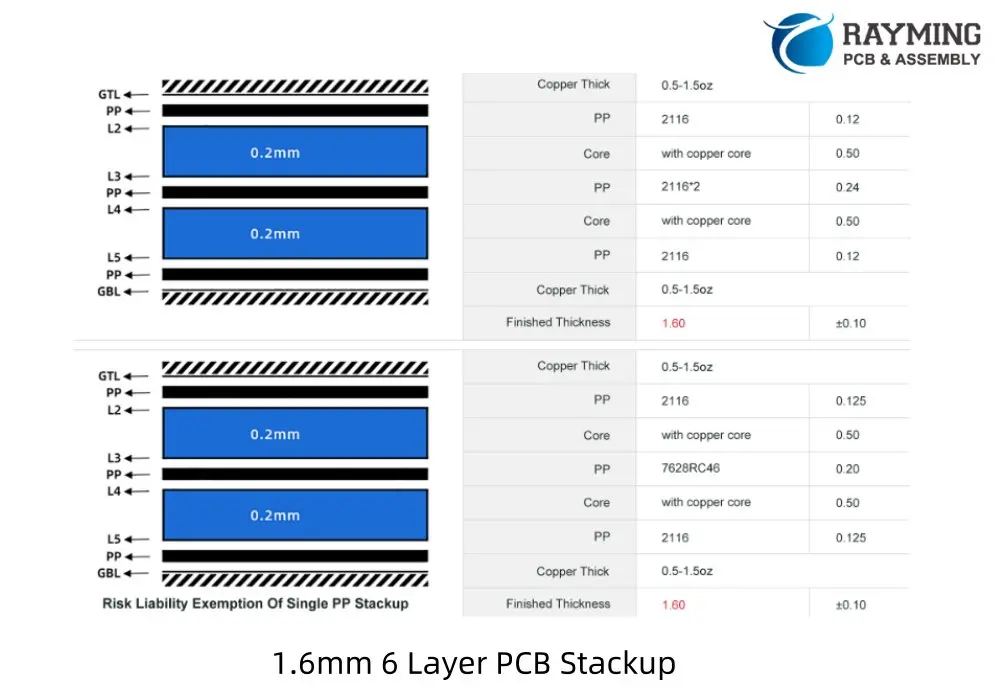

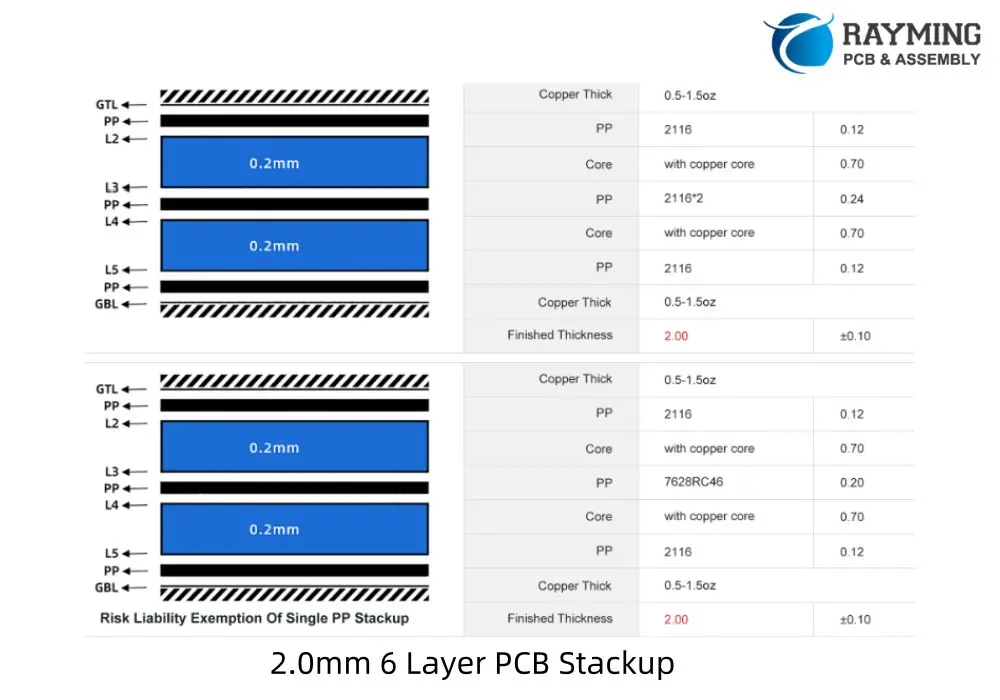

6 Layer PCB stackup reference for different thickness:

- Read more about: 4 Layer PCB Stackup

If you need stackup suggestion for your 6 layer PCB design, welcome to contact us.