RF PCB Design Suite

Comprehensive engineering tools for high-frequency PCB design. Calculate impedance, compare materials, estimate costs, and optimize your RF designs.

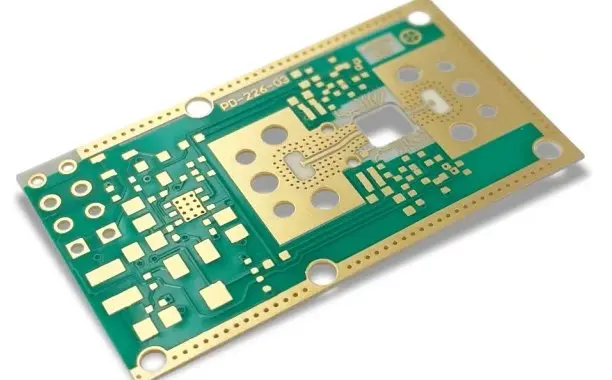

Calculate transmission line impedance for various geometries with RF substrate materials.

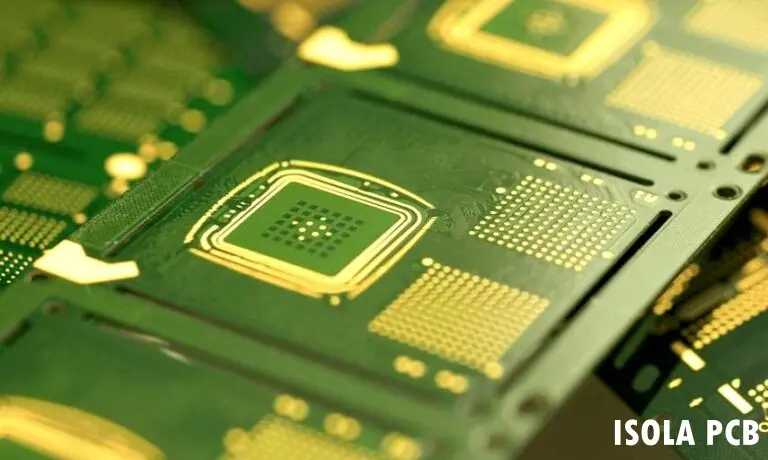

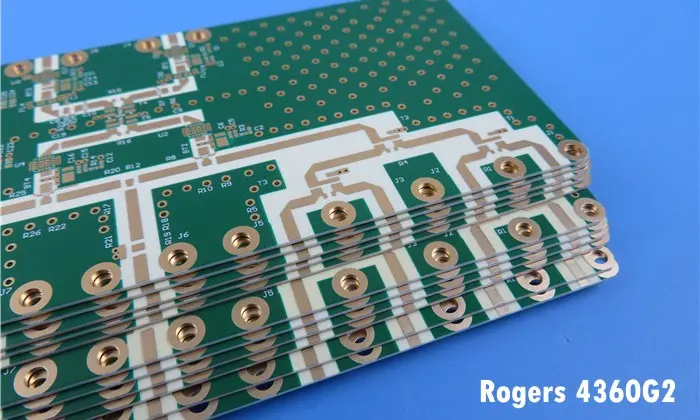

Compare Rogers, Taconic, Arlon, Isola, and more with detailed electrical properties.

Get estimated manufacturing costs based on material, layers, and specifications.

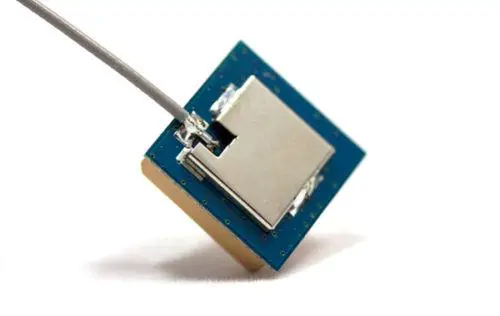

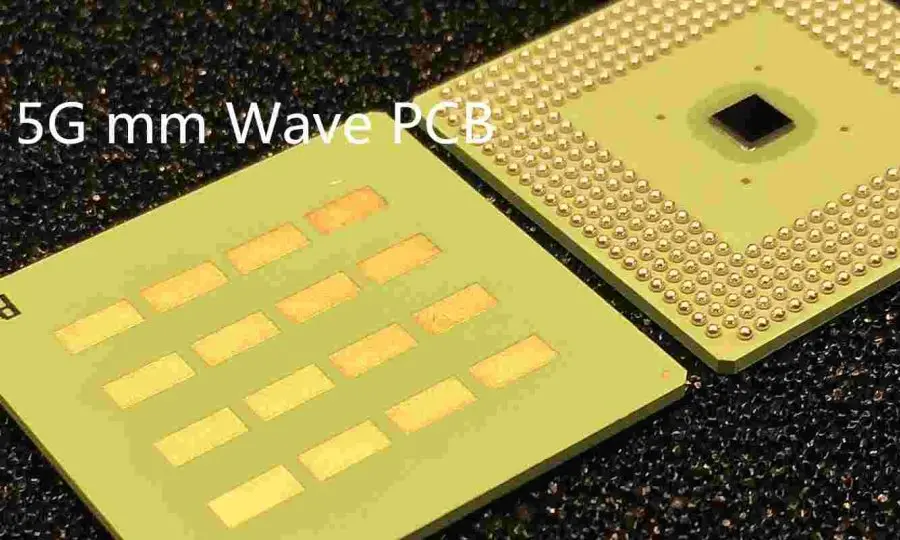

For frequencies above 10 GHz, consider materials with Df < 0.003 to minimize signal loss. Rogers RO3003 and Taconic TLY-5 are excellent choices for mmWave applications.

| Material | Manufacturer | Dk @10GHz | Df @10GHz | Thickness (mm) | CTE Z (ppm/°C) | Tg (°C) | Thermal K | Max Freq | Cost Index |

|---|

Rogers RT/duroid 5880, Taconic TLY-5, Arlon CLTE-XT

Rogers RO3003, Taconic TLX-8, Isola Astra MT77

Rogers RO3003, RO4835, Taconic RF-35

Rogers RO4350B, Megtron 6, Isola I-Tera MT40

• For 50Ω microstrip: W ≈ 2×H for εr ≈ 4

• Keep W/H between 0.5 and 4 for accurate models

• Consider via spacing for ground return path

• Edge coupling increases with narrower spacing

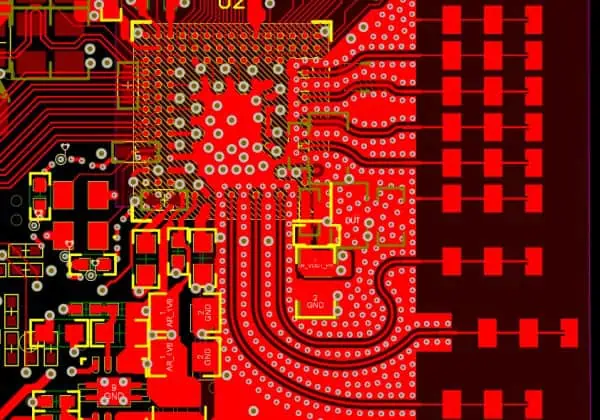

| Layer | Type | Material | Thickness |

|---|---|---|---|

| L1 | Signal (RF) | RO4350B | 35 μm Cu |

| - | Prepreg | RO4450F | 0.1 mm |

| L2 | Ground | - | 35 μm Cu |

| - | Core | FR-4 | 1.0 mm |

| L3 | Power | - | 35 μm Cu |

| - | Prepreg | FR-4 PP | 0.2 mm |

| L4 | Signal | - | 35 μm Cu |

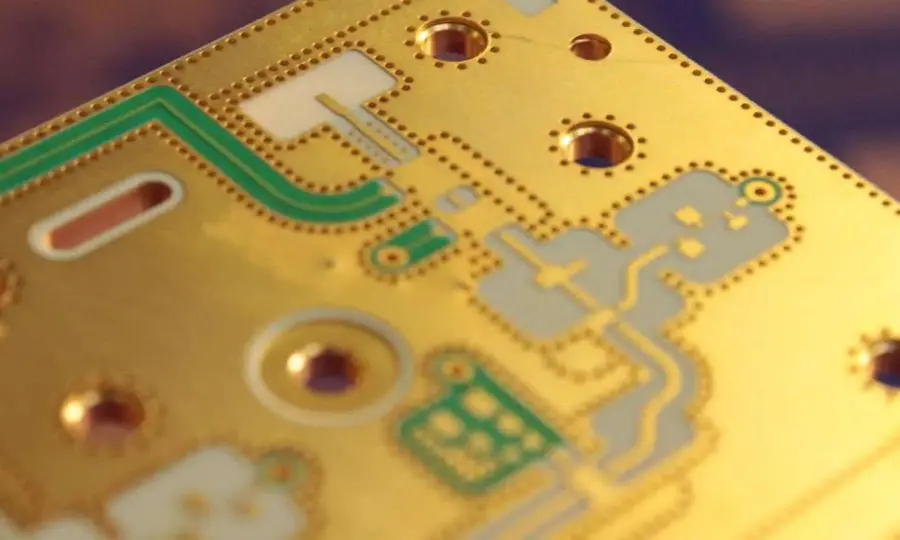

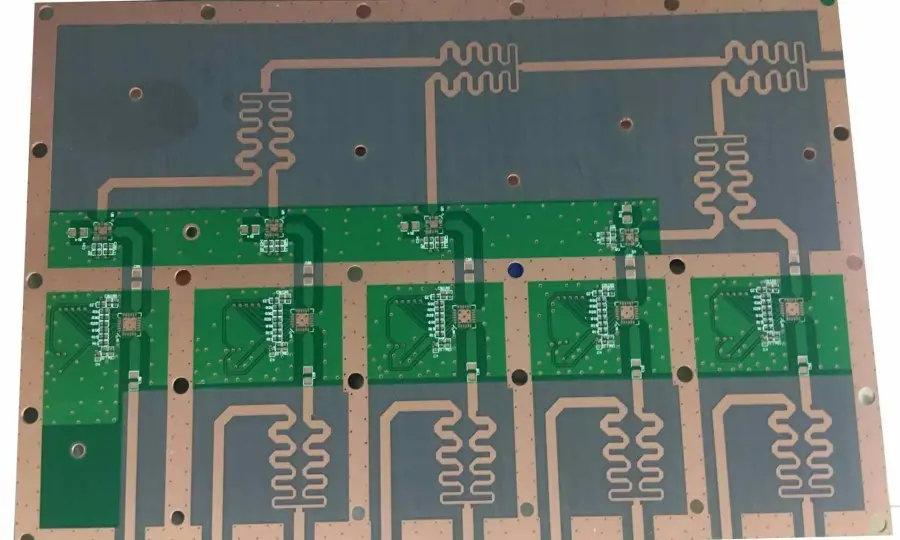

• Place RF traces on outer layers adjacent to ground

• Use continuous ground plane under RF routing

• Consider thermal relief for RF components

• Match Dk between prepreg and core for hybrid stacks

This is an estimate only. Actual costs vary by manufacturer, lead time, and specific requirements. Contact RayPCB for accurate quotes.

λ₀ = c / f = 299.792 / f(GHz) mm

λg = λ₀ / √εeff

δ = √(ρ / πfμ)

For copper: δ ≈ 66/√f(MHz) μm

αd = 27.3 × (εr/εeff) × (εeff-1)/(εr-1) × (tan δ/λ₀) dB/length

tpd = √εeff / c ≈ 3.33√εeff ps/mm

L ≈ 5.08h[ln(4h/d) + 1] nH

h = via height (in), d = via diameter (in)

• 50Ω microstrip: W ≈ 1.8-2× substrate height (εr≈4)

• Keep W/H ratio between 0.5 and 4

• Match trace widths at transitions

• Ground via spacing < λ/10

• Via stub length < λ/20 for mmWave

• Use back-drilling for high-frequency

• Multiple vias reduce inductance

• Solid ground plane under RF traces

• Avoid splits/slots under RF routing

• Via stitch ground around RF sections

• Star ground for mixed-signal

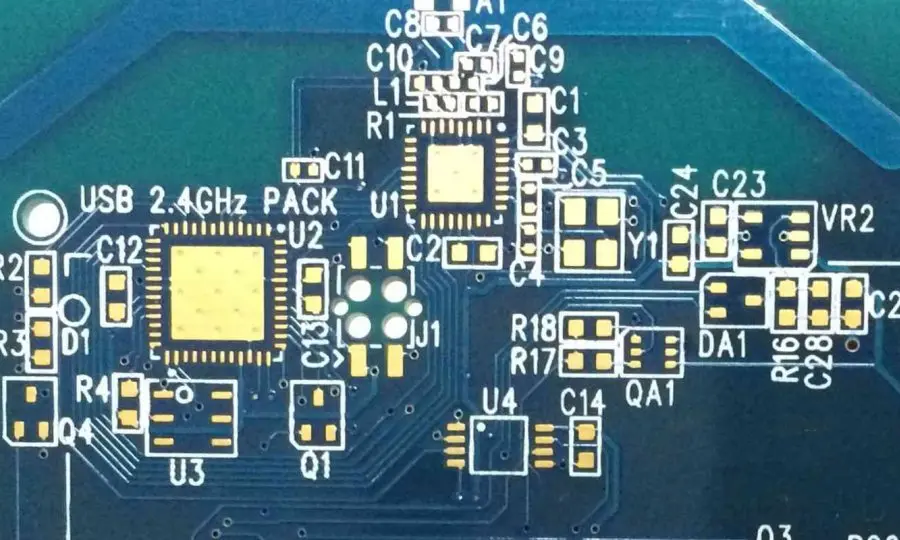

• Keep RF traces short and direct

• 45° or curved bends, no 90° corners

• Maintain consistent trace width

• Isolate RF from digital/power

Length

| 1 mil | = | 0.0254 mm |

| 1 mm | = | 39.37 mil |

| 1 inch | = | 25.4 mm |

| 1 μm | = | 0.0394 mil |

Copper Weight

| 0.5 oz | = | 17.5 μm |

| 1 oz | = | 35 μm |

| 2 oz | = | 70 μm |

| 3 oz | = | 105 μm |

Frequency

| 1 GHz | = | 1000 MHz |

| λ @ 1 GHz | = | 300 mm |

| λ @ 10 GHz | = | 30 mm |

| λ @ 77 GHz | = | 3.9 mm |