Gold Plating PCB: Complete Guide to Types, Benefits & Process

Hard gold plating is an electroplated surface finish that deposits a durable gold alloy coating onto specific PCB areas, providing exceptional wear resistance and electrical conductivity.

After working with circuit boards for over a decade, I can tell you that choosing the right surface finish can make or break your product. Gold plating PCB has become my go-to recommendation for clients who need reliability, excellent conductivity, and long-term performance. Whether you’re designing aerospace electronics, medical devices, or high-frequency communication systems, understanding gold plating options will help you make better decisions for your next project.

In this comprehensive guide, I’ll walk you through everything you need to know about gold plating on printed circuit boards, from the fundamental processes to real-world application considerations.

What Is Gold Plating on PCB?

Gold plating PCB is an electrochemical process that deposits a thin layer of gold onto the copper traces and contact points of circuit boards. The gold layer serves as a protective barrier that prevents oxidation and corrosion while providing excellent electrical conductivity.

The process typically involves several key steps. First, the copper surface gets cleaned and prepared thoroughly. Then, a nickel layer is electroplated onto the copper surface to create a strong adhesion base. Finally, a thin layer of gold is electroplated over the nickel layer. The resulting gold-plated surface is extremely thin, typically ranging from 0.03 to 2.5 microns depending on the application requirements.

From my experience working on hundreds of PCB projects, gold plating offers three primary advantages that other surface finishes simply cannot match: superior corrosion resistance, excellent electrical conductivity, and exceptional longevity.

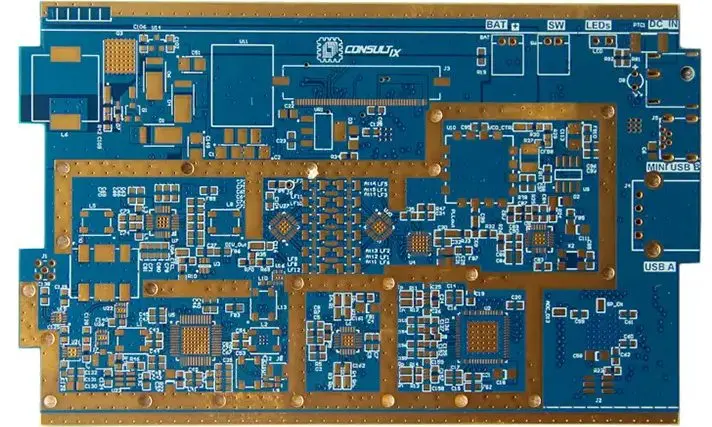

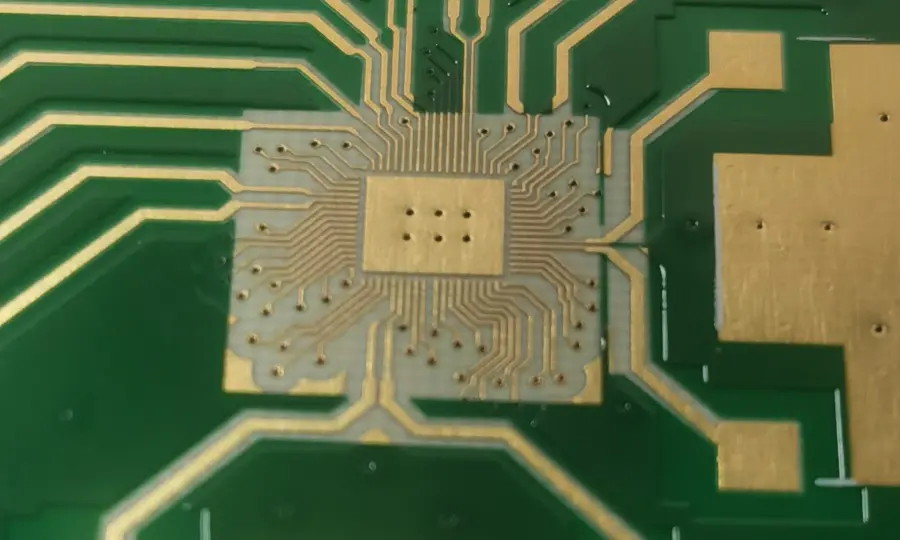

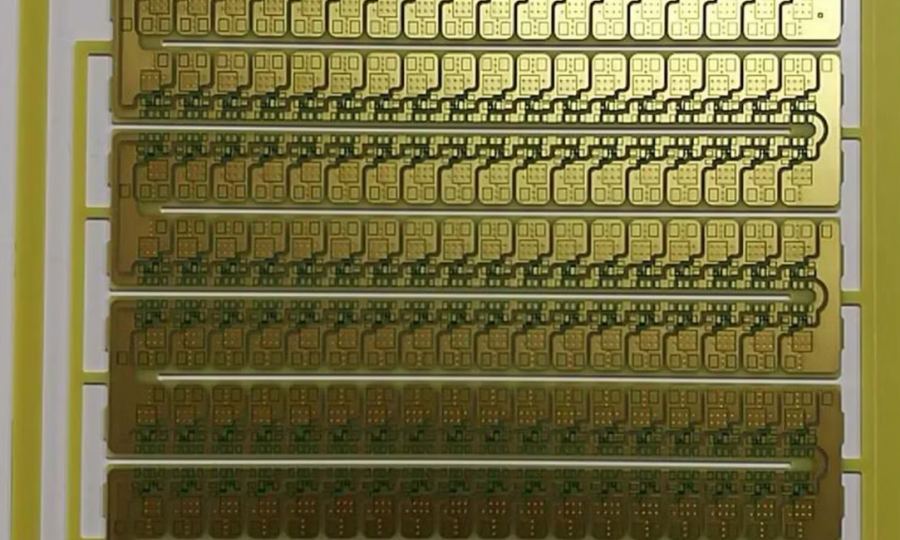

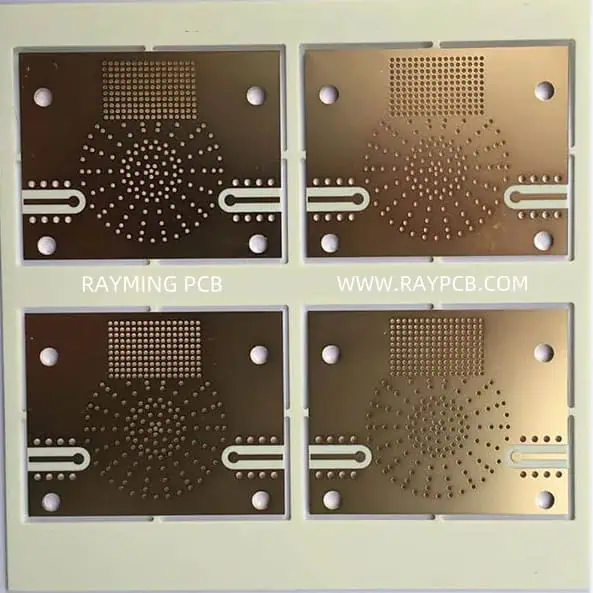

Gold Plating PCB We Served

5u” Hard Gold PCB

10u” Hard Gold PCB

20u” Hard Gold PCB

50u” Hard Gold PCB

Why Use Gold Plating on PCB?

Before diving into the technical details, let me explain why gold plating PCB matters in the first place.

Corrosion Prevention

Bare copper PCBs have excellent electrical conductivity but poor corrosion resistance. Exposed copper readily oxidizes when contacted by oxygen and moisture, developing a dark tarnish within days of exposure to air. This oxidation creates a resistive oxide layer that degrades electrical performance and makes soldering difficult.

Gold plating completely eliminates copper oxidation, maintaining electrical properties indefinitely. I’ve tested boards that sat in storage for years and still performed perfectly because of their gold finish.

Superior Electrical Performance

Gold offers stable, low-contact resistance and high conductivity, making it ideal for usage on a PCB’s connecting points. The superior conductivity ensures signal integrity, especially important for high-frequency applications where even minor resistance variations can cause problems.

Extended Service Life

For applications requiring long-term storage or operation in corrosive environments, gold plating provides unmatched protection. Gold-plated PCBs can withstand thousands of insertion cycles without significant wear, making them perfect for connectors and edge fingers.

RayPCB Engineering Tools

Based on your insertion cycle requirements, the recommended gold thickness ensures optimal wear resistance and electrical performance for your application.

• Minimize gold finger area where possible

• Consider ENIG for areas not requiring insertion wear resistance

• Order in larger quantities for volume discounts

• Standard thicknesses (30-50 μ") are more cost-effective

| Parameter | Specification |

|---|---|

| Gold Thickness | 1.27 μm (50 μ") |

| Nickel Underplate | 3.8 - 5.0 μm (150-200 μ") |

| Gold Purity | 99.7% min (Hard Gold with Co/Ni) |

| Hardness | 130-200 HV (Knoop) |

| Insertion Cycles | 500-1000 cycles |

| Contact Resistance | < 20 mΩ initial |

Design Note: Hard gold areas should be kept separate from ENIG/ENEPIG surface finish areas. Use solder mask to define boundaries clearly. Ensure adequate clearance from solder joints.

| Property | Hard Gold (Electroplated) | Soft Gold (ENIG/ENEPIG) |

|---|---|---|

| Hardness | 130-200 HV | 60-85 HV |

| Purity | 99.7% (Co or Ni alloyed) | 99.9%+ pure |

| Typical Thickness | 0.5 - 2.5 μm | 0.05 - 0.15 μm |

| Wear Resistance | Excellent | Poor |

| Solderability | Fair (not recommended) | Excellent |

| Wire Bonding | Not suitable | Excellent |

| Cost | Higher (area-dependent) | Lower (full surface) |

| Primary Use | Edge connectors, contacts | SMD pads, BGA |

| Standard | Description | Key Requirements |

|---|---|---|

| IPC-4552 | ENIG Specification | Au: 0.05-0.23 μm, Ni: 3-6 μm |

| IPC-4556 | ENEPIG Specification | Au: 0.03-0.08 μm, Pd: 0.05-0.15 μm |

| MIL-G-45204 | Gold Plating (Military) | Type I/II/III, Class 0-4 |

| ASTM B488 | Electrodeposited Gold | Type I-III, Grades A-D |

• XRF Analysis: Non-destructive thickness measurement

• Tape Test: Adhesion verification per ASTM D3359

• Microhardness: Knoop or Vickers hardness testing

• Porosity Test: Nitric acid vapor or electrographic

• Contact Resistance: Four-point probe measurement

Types of Gold Plating for PCB

Understanding the different types of gold plating PCB options is crucial for selecting the right finish for your specific application. Each method has distinct characteristics that make it suitable for different use cases.

ENIG (Electroless Nickel Immersion Gold)

ENIG, or Electroless Nickel Immersion Gold, is currently the most widely used gold surface finish in the PCB industry. The process involves depositing a nickel layer through an autocatalytic chemical reaction, followed by a thin gold layer through immersion.

ENIG Layer Composition:

- Nickel layer: 3-6 microns (118.1 to 236.2 microinches)

- Gold layer: 0.05-0.125 microns (1.97 to 4.925 microinches)

The nickel layer serves as a barrier to prevent copper diffusion, while the thin gold layer protects the nickel during storage and provides excellent solderability. ENIG creates a smooth, flat surface that’s perfect for fine-pitch components, BGAs, and other high-density assemblies.

Key Characteristics of ENIG:

- Excellent flatness for fine-pitch component assembly

- Good solderability and wetting properties

- Suitable for wire bonding applications

- Lead-free and RoHS compliant

- Longer shelf life compared to many alternatives

However, ENIG does have limitations. The gold layer is relatively thin and soft, making it unsuitable for areas requiring frequent mechanical contact. There’s also a potential issue called “black pad” where nickel corrosion can occur if process control isn’t properly maintained.

Hard Gold Plating (Electrolytic Hard Gold)

Hard gold plating, also known as electrolytic hard gold, involves depositing a thicker layer of gold through an electroplating process. Unlike ENIG, hard gold is alloyed with small amounts of cobalt or nickel (typically 5-10%) to enhance hardness and wear resistance.

Hard Gold Layer Composition:

- Nickel underlayer: 2.5-5 microns (100-200 microinches)

- Gold layer: 0.76-2.5 microns (30-100 microinches)

The thicker gold layer and alloying metals make hard gold extremely durable. It can withstand up to 1,000 insertion cycles without significant wear, making it ideal for edge connectors (gold fingers), keypads, and other high-wear areas.

Key Characteristics of Hard Gold:

- Exceptional wear resistance

- Superior hardness (130-200 Knoop Hardness Number)

- Withstands frequent mechanical contact

- Gold purity minimum 99.7% per MIL-G-45204

- Not ideal for soldering due to alloy content

The main drawback of hard gold plating is cost. The thicker gold layer and more complex electroplating process make it significantly more expensive than ENIG. Additionally, the alloying elements that provide hardness also reduce solderability.

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

ENEPIG adds a palladium layer between the nickel and gold layers, creating a three-layer metallic coating. This surface finish addresses some of ENIG’s limitations while providing additional benefits.

ENEPIG Layer Composition:

- Nickel layer: 3-5 microns

- Palladium layer: 0.1-0.2 microns

- Gold layer: 0.05-0.15 microns

The palladium layer prevents nickel from oxidizing before gold immersion (which causes black pad defects), improves solder reliability, and provides better wire bonding capability.

Key Characteristics of ENEPIG:

- Eliminates black pad risk

- Excellent for wire bonding applications

- Superior corrosion resistance

- Compatible with both lead-free and traditional solders

- Higher cost than ENIG

ENEPIG is often called a “universal” finish because it can handle almost any assembly process. However, the additional palladium layer increases cost, and not all PCB manufacturers have the capability to process ENEPIG.

Soft Gold Plating

Soft gold plating uses pure gold (99.9%) without alloying metals. This creates a softer, more malleable finish that’s excellent for wire bonding but poor for wear resistance.

Soft Gold Characteristics:

- Pure gold with no alloying elements

- Excellent for wire bonding

- Very thin layer (0.03-0.1 microns typical)

- Not suitable for mechanical contact areas

- Better solderability than hard gold

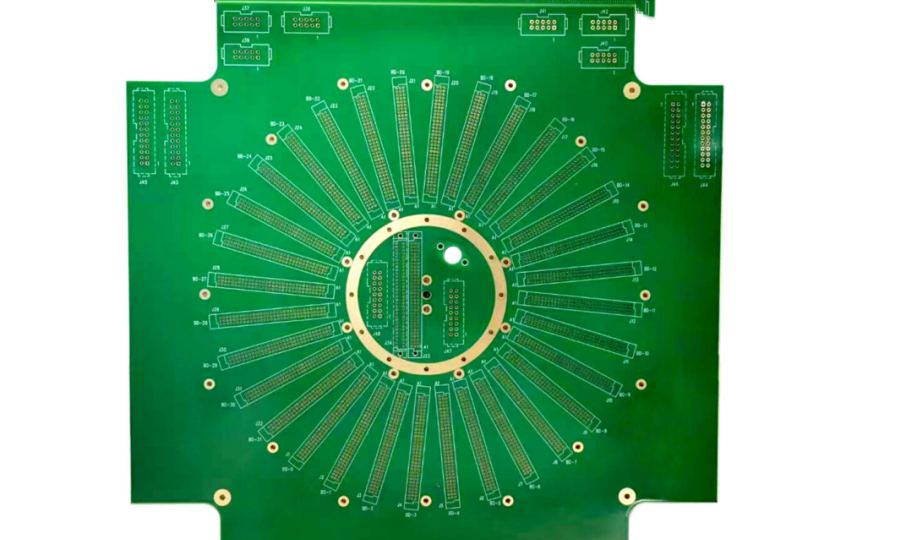

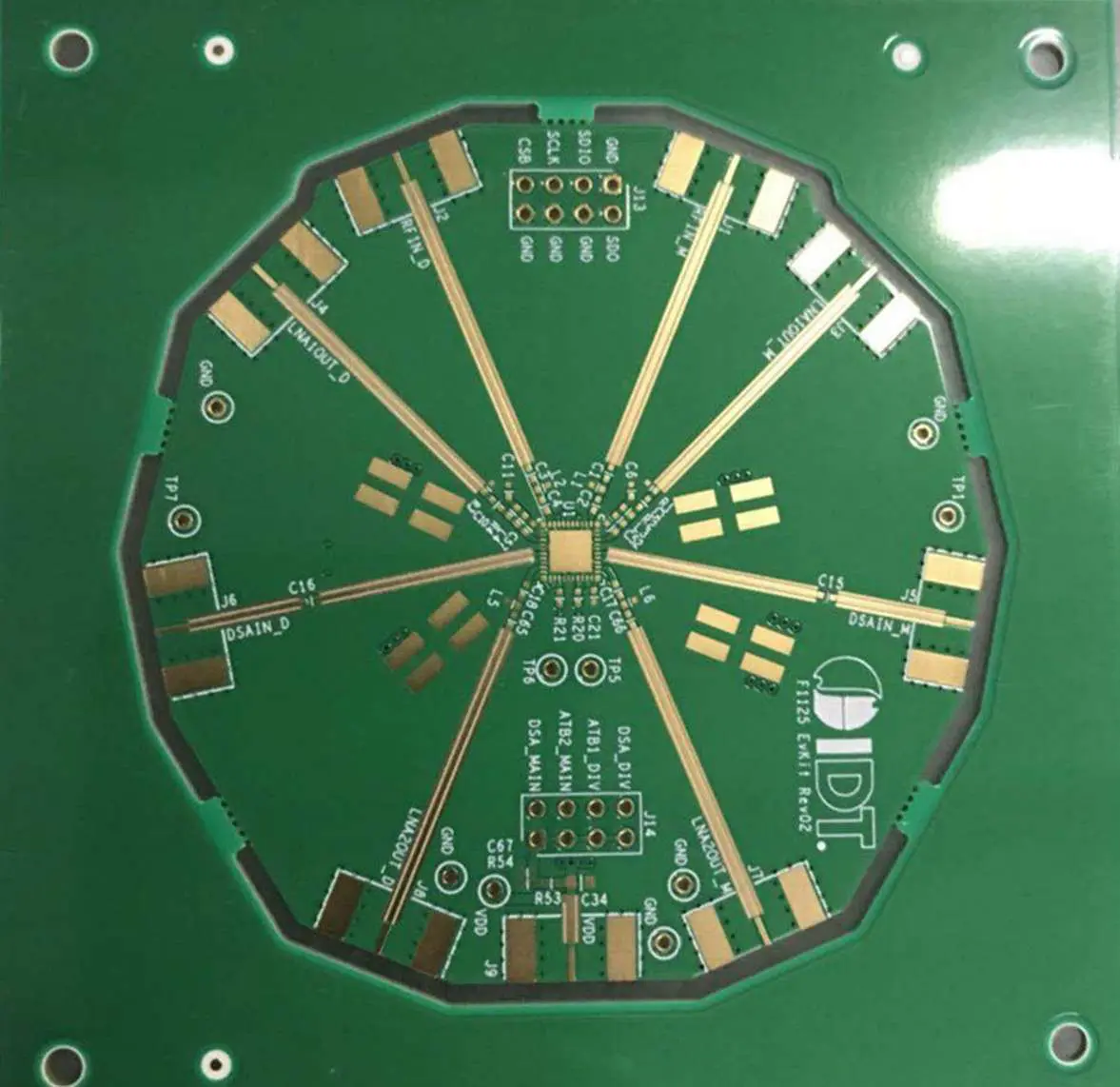

Selective Gold Plating

Selective gold plating applies hard gold only to specific areas of the PCB that require wear resistance, while other areas use different finishes like ENIG or OSP. This approach optimizes cost while providing the right finish where it’s needed most.

Common applications include gold fingers on edge connectors combined with ENIG on soldering pads. This requires precise masking during manufacturing and adds complexity to the production process.

Gold Plating PCB Type Comparison Table

| Feature | ENIG | Hard Gold | ENEPIG | Soft Gold |

|---|---|---|---|---|

| Gold Thickness | 0.05-0.125 µm | 0.76-2.5 µm | 0.05-0.15 µm | 0.03-0.1 µm |

| Nickel Thickness | 3-6 µm | 2.5-5 µm | 3-5 µm | 3-6 µm |

| Hardness (HK) | 20-100 | 130-200 | 50-90 | 20-60 |

| Wear Resistance | Low | Excellent | Moderate | Very Low |

| Solderability | Excellent | Poor | Excellent | Good |

| Wire Bonding | Good | Poor | Excellent | Excellent |

| Insertion Cycles | <50 | 1000+ | 100-200 | <20 |

| Relative Cost | Medium | High | High | Medium |

| Black Pad Risk | Possible | None | None | Possible |

| RoHS Compliant | Yes | Yes | Yes | Yes |

Gold Plating PCB Process Step by Step

Understanding the gold plating PCB process helps you specify requirements correctly and troubleshoot potential issues. Here’s how the typical electroplating process works for hard gold plating on gold fingers:

Step 1: Surface Preparation and Cleaning

Before any plating can occur, the PCB undergoes thorough cleaning. Any contaminants like oils, dust, or oxides on the copper pads interfere with adhesion during plating. The board is cleaned using alkaline solutions or micro-etching to remove impurities and create a uniform surface.

After chemical cleaning, mechanical abrasion further cleans the PCB pads. The board is then rinsed with water and a final deionized water rinse removes any remaining chemicals. Even minor residues can lead to uneven plating or poor bonding between layers.

Step 2: Masking

For selective gold plating, areas that shouldn’t receive gold are masked with protective tape or photoresist. This is especially important for gold fingers where only the connector edges need the hard gold finish.

Step 3: Nickel Plating

A layer of nickel is electroplated onto the copper pads. Nickel plating serves as a barrier layer, preventing copper from migrating into the gold coating, which could cause corrosion or reduced conductivity over time.

Typical nickel thickness ranges from 2.5 to 5 microns (100-200 microinches). The PCB is immersed in a solution containing nickel salts, and an electric current deposits a uniform nickel layer on the prepared surfaces.

Step 4: Gold Electroplating

With the nickel layer in place, gold is electroplated onto the surface. The board is immersed in a gold plating bath containing gold salts (typically potassium gold cyanide), and electrical current deposits gold onto the nickel layer.

For hard gold, the bath also contains alloying metals like cobalt. Plating thickness is controlled by adjusting current density, bath composition, and plating time. Typical hard gold thickness ranges from 30 to 50 microinches for general applications, up to 100 microinches for high-wear requirements.

Step 5: Quality Inspection and Testing

After plating, the boards undergo thorough inspection. Key tests include:

- Thickness measurement: Using X-ray fluorescence (XRF) to verify gold and nickel thickness

- Adhesion testing: Per ASTM B571 to ensure proper bonding

- Visual inspection: Checking for scratches, pitting, or discoloration

- Hardness testing: Verifying the gold layer meets hardness specifications

Step 6: Final Processing

The masking materials are removed, and the board continues through normal manufacturing steps like solder mask application and final assembly.

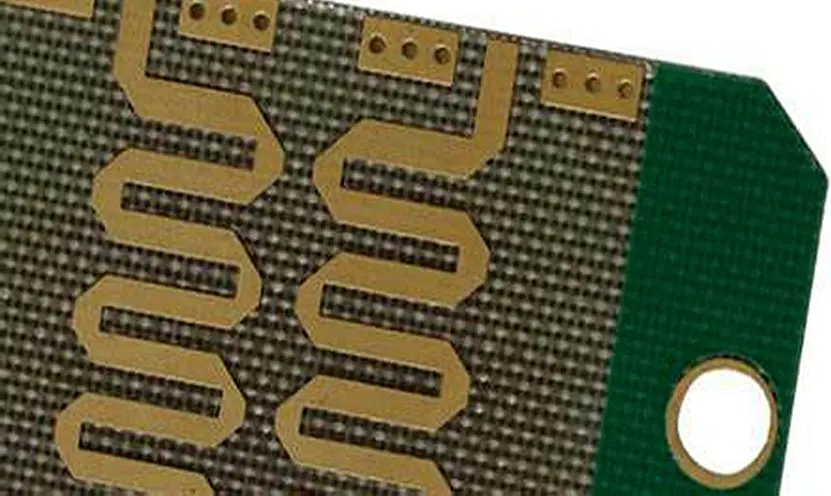

Gold Finger Design Requirements for PCB

Proper design is crucial for manufacturing reliable gold finger PCBs. Here are the essential design rules I always follow:

Spacing and Clearance Rules

- Keep plated through-holes at least 1mm away from gold fingers

- Maintain clearance between gold fingers and solder mask

- Ensure clearance between gold fingers and silkscreen printing

- Orient fingers on the outside edge of the board facing away from the center

Dimensional Requirements

- Gold fingers can be placed on one or both sides of a board

- Maximum depth from outer edge is typically 1 inch

- Connect fingers with 8 mil minimum conductor traces

- No copper should exist in internal PCB layers under the gold finger area

Edge Beveling

Connector edges are beveled at specific angles (typically 20-45 degrees) to facilitate smooth insertion into mating connectors. Beveling prevents damage during insertion and reduces wear on both the connector and the mated slot.

IPC Standards for Gold Plating PCB

Compliance with industry standards ensures quality and reliability. Here are the key standards governing gold plating PCB:

IPC-4552 (ENIG Specification)

This standard covers requirements for electroless nickel immersion gold plating. Key specifications include:

- Gold thickness: 0.05-0.125 µm typical range

- Nickel thickness: 3-6 µm

- Corrosion resistance requirements

- Testing methods for nickel corrosion (black pad)

IPC-4552B introduced quantifiable methods for measuring nickel corrosion frequency and severity, helping manufacturers control quality more effectively.

IPC-4556 (ENEPIG Specification)

This standard defines requirements for the three-layer ENEPIG finish:

- Gold thickness: 0.025-0.07 µm

- Palladium thickness: 0.05-0.15 µm

- Nickel thickness: 3-6 µm

IPC-6012 (Rigid PCB Qualification)

This standard includes specifications for hard gold plating:

- Class 1 (General Electronics): 5-10 microinches gold minimum

- Class 2 (Dedicated Service): 30 microinches gold minimum

- Class 3 (High Reliability): 30-50 microinches gold minimum

MIL-G-45204 (Military Specification)

For military and aerospace applications, this standard specifies:

- Gold purity minimum 99.7%

- Hardness 130-200 Knoop

- Detailed testing requirements

Gold Plating PCB Cost Considerations

Cost is always a factor in surface finish selection. Here’s what affects gold plating PCB pricing:

Cost Factors

| Factor | Impact on Cost |

|---|---|

| Gold thickness | Higher thickness = higher cost (gold is expensive) |

| Plating area | Larger gold areas increase material cost |

| Selective vs. full plating | Selective plating adds processing steps |

| Volume | Higher volumes reduce per-unit cost |

| Complexity | Multi-layer boards cost more to plate |

| IPC Class | Higher reliability classes require tighter tolerances |

Cost Comparison by Finish Type

As a rough guide, here’s how different finishes compare cost-wise:

- HASL (Lead-Free): Baseline cost

- OSP: Similar to HASL or slightly lower

- ENIG: 15-30% premium over HASL

- ENEPIG: 35-60% premium over HASL

- Hard Gold: 50-100%+ premium depending on thickness

The actual premium depends heavily on gold prices, which fluctuate with the commodities market.

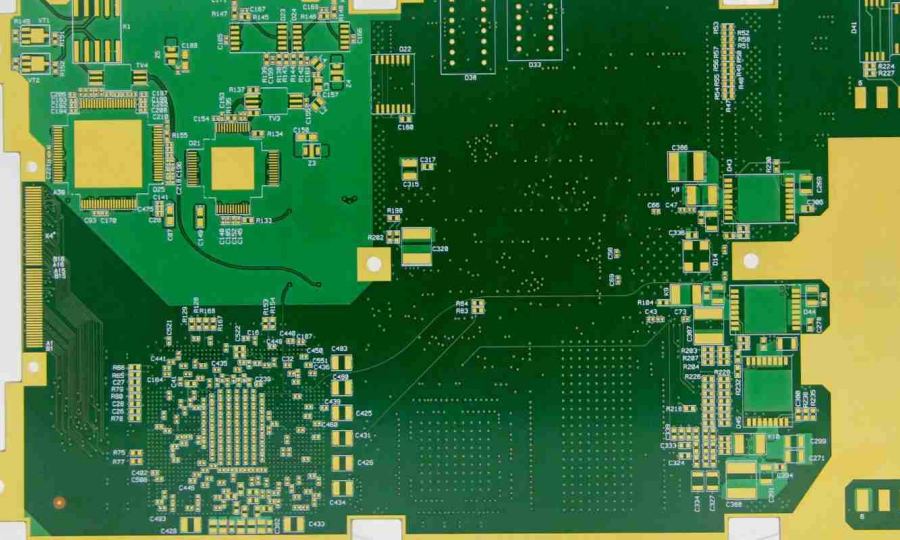

Applications of Gold Plating PCB

Gold plating PCB finds use across numerous industries where reliability and performance are critical.

Aerospace and Military

Gold-plated PCBs are standard in aerospace and military applications where reliability is non-negotiable. Aircraft avionics, satellite communications, and military guidance systems use gold plating to ensure long-term functionality in demanding environments. The extended shelf life is particularly valuable in defense applications where equipment may be stored for years before deployment.

Medical Devices

Implantable and external medical devices require exceptional biocompatibility and long-term reliability. Gold plating provides corrosion resistance that prevents metal ion leaching that could trigger allergic reactions or tissue damage. Pacemakers, hearing aids, surgical instruments, and diagnostic equipment commonly employ gold plating.

Consumer Electronics

While cost constraints limit gold plating use in low-end products, premium consumer electronics benefit from gold plating in high-wear areas. Memory sticks, graphics cards, and other expansion cards use gold fingers for reliable connections to motherboards.

Telecommunications

High-frequency communication equipment requires stable, low-resistance connections. Gold plating PCB ensures signal integrity in 5G infrastructure, satellite systems, and networking equipment.

Industrial Equipment

Industrial control systems, automation equipment, and test instruments often use gold plating for connectors and switches that see frequent use. The superior wear resistance ensures years of reliable operation.

Gold Plating PCB Thickness Guide

Selecting the right gold thickness depends on your specific application. Here’s a practical guide:

| Application | Recommended Gold Thickness | Notes |

|---|---|---|

| SMD Pads (ENIG) | 0.05-0.125 µm | Standard for soldering |

| Wire Bonding | 0.3+ µm (ENIG) or ENEPIG | Thicker gold needed |

| Low-frequency connectors | 10-20 microinches | Minimal wear |

| General gold fingers | 30 microinches | IPC Class 2/3 minimum |

| High-wear connectors | 50 microinches | Thousands of cycles |

| Extreme applications | 50-100 microinches | Military, aerospace |

Choosing Between Gold Plating PCB Options

Making the right choice between different gold plating PCB options can be challenging. Here’s my decision framework based on years of practical experience:

When to Choose ENIG

Select ENIG when your primary concern is solderability and you have fine-pitch components like BGAs, QFPs, or CSPs. ENIG works well for products that won’t experience mechanical wear on the plated surfaces. It’s cost-effective for mass production and provides excellent shelf life.

Ideal applications include consumer electronics, telecommunications equipment, and any product with complex SMD assembly requirements. The flat, coplanar surface makes ENIG perfect for high-density interconnect (HDI) boards.

When to Choose Hard Gold

Choose hard gold plating when durability matters more than solderability. Edge connectors, switch contacts, test points that see repeated probe contact, and keyboard contacts all benefit from hard gold’s wear resistance.

I always recommend hard gold for any connector expected to see more than 100 insertion cycles. The upfront cost premium pays off quickly when you consider the cost of field failures from worn-out contacts.

When to Choose ENEPIG

ENEPIG makes sense when you need wire bonding capability or when black pad risk is unacceptable. Medical devices, aerospace electronics, and high-reliability applications often specify ENEPIG for its superior performance characteristics.

If your product requires both excellent solderability and wire bonding, ENEPIG is really the only practical choice. The palladium layer provides insurance against nickel corrosion issues that can plague ENIG in some environments.

When to Use Selective Gold Plating

Selective gold plating combines the best of multiple finishes. Use hard gold on edge connectors while applying ENIG to SMD pads. This approach optimizes cost without compromising performance where it matters.

The added manufacturing complexity requires clear communication with your PCB fabricator. Provide detailed drawings showing exactly which areas require each finish type.

Common Gold Plating PCB Problems and Solutions

Even with proper processes, problems can occur. Here are issues I’ve encountered and how to address them:

Black Pad (Nickel Corrosion)

Black pad occurs when nickel corrodes before or after gold immersion, creating weak solder joints. Prevention involves proper process control including bath chemistry monitoring, temperature control, and limiting time between plating steps. Using ENEPIG instead of ENIG eliminates this risk.

Poor Adhesion

Inadequate surface preparation causes poor adhesion between layers. Ensure thorough cleaning and proper activation before plating. Adhesion testing per ASTM B571 should be part of quality control.

Thickness Variation

Inconsistent gold thickness results from non-uniform current distribution during electroplating. Proper anode placement, bath agitation, and current density control minimize variations. XRF measurement at multiple points verifies uniformity.

Pitting and Porosity

Surface defects can result from contamination, improper bath chemistry, or incorrect plating parameters. Regular bath analysis and maintenance prevents most issues.

Resources for Gold Plating PCB

Here are valuable resources for further learning:

Industry Standards

- IPC-4552B: ENIG specification (available from IPC website)

- IPC-4556: ENEPIG specification

- IPC-6012: Rigid PCB qualification and performance

- MIL-G-45204: Military hard gold plating specification

- ISO 4524: Test methods for gold coatings

Technical References

- IPC Plating Committee publications

- ASTM B488: Gold coating testing standard

- ASTM B571: Adhesion testing methods

Industry Organizations

- IPC (Association Connecting Electronics Industries): www.ipc.org

- SMTA (Surface Mount Technology Association): www.smta.org

Best Practices and Recommendations

Design Optimization

To achieve optimal results with hard gold plating in PCB design, follow these best practices tailored for engineers and designers.

Specification Clarity

Specify Plating Areas Clearly: Use design files to indicate exactly where hard gold plating is needed, such as on edge connectors or specific pads.

Documentation Requirements:

- Clear fabrication drawings

- Detailed specification notes

- Thickness requirements by area

- Quality standards reference

Thickness Selection

Choose the Right Thickness: Match the gold thickness to the application’s wear and environmental requirements. For instance, use 0.8-1.3 microns for moderate wear and up to 2.5 microns for high-cycle applications.

Substrate Preparation

Ensure Proper Nickel Underlayer: A uniform nickel layer of 3-6 microns is critical for adhesion and durability. Specify this in your design requirements to avoid issues like gold peeling.

Manufacturing Partnership

Collaborate with Manufacturers Early: Work closely with your PCB fabrication partner during the design phase to confirm that your hard gold plating requirements are feasible and cost-effective.

Partnership Benefits:

- Early design feedback

- Process optimization opportunities

- Cost reduction strategies

- Quality assurance planning

Quality Assurance

Implement comprehensive quality control throughout the design and manufacturing process:

QA Checkpoints:

- Design rule verification

- Process qualification

- In-process monitoring

- Final inspection and testing

- Field performance tracking

Frequently Asked Questions About Gold Plating PCB

What is the difference between ENIG and hard gold plating?

ENIG uses a chemical process to deposit a thin gold layer (0.05-0.125 µm) over electroless nickel, making it excellent for soldering but poor for wear resistance. Hard gold plating uses an electroplating process to deposit a thicker gold layer (0.76-2.5 µm) alloyed with cobalt, making it extremely durable for connectors but unsuitable for soldering. Choose ENIG for SMD assembly and hard gold for edge connectors and high-wear contacts.

How thick should gold plating be on PCB gold fingers?

For most applications, 30 microinches (0.76 µm) of hard gold over 100-150 microinches of nickel meets IPC Class 2 and Class 3 requirements. High-reliability applications like military or aerospace may require 50 microinches (1.27 µm) or more. Consumer electronics with fewer insertion cycles can use thinner plating (10-20 microinches) to reduce costs.

Can you solder to hard gold plated surfaces?

Hard gold plating is not recommended for soldering. The cobalt or nickel alloying elements that provide wear resistance interfere with solder wetting and can cause brittle solder joints. For surfaces requiring both wear resistance and solderability, use selective plating with hard gold on contacts and ENIG or ENEPIG on SMD pads.

What causes black pad defect in ENIG?

Black pad occurs when nickel corrodes during the immersion gold process or afterward due to phosphorus segregation at the nickel surface. The defect appears as a dark layer between nickel and gold that causes solder joint failures. Prevention requires proper process control including bath chemistry, temperature, and dwell time. Switching to ENEPIG eliminates black pad risk because the palladium layer protects nickel during gold immersion.

Is gold plating PCB RoHS compliant?

Yes, all gold plating PCB processes including ENIG, ENEPIG, and hard gold are RoHS compliant. Gold, nickel, and palladium are not restricted substances under RoHS regulations. Gold plating has actually become more popular since RoHS implementation because it provides a reliable lead-free surface finish suitable for lead-free soldering processes.

Conclusion

Selecting the right gold plating PCB finish requires balancing performance requirements, application demands, and budget constraints. ENIG remains the most popular choice for general SMD assembly due to its excellent solderability and reasonable cost. Hard gold plating is essential for edge connectors and high-wear applications. ENEPIG offers the best of both worlds for demanding applications willing to pay the premium.

Whatever finish you choose, proper design, specification to IPC standards, and working with experienced manufacturers ensures your gold-plated PCBs will deliver the reliability and performance your products demand.

If you have questions about gold plating for your specific application, work closely with your PCB manufacturer early in the design process. Getting the surface finish right from the start saves time, money, and headaches down the road.